Tanks and stainless steel equipment for wine, beer and oil

Prettech - Machinery & Technology

Jiangsu Prettech Machinery & Technology Co., Ltd is focused on Consulting & designing, Fabricating, OEM, Project contracting, Installing & commission of stainless steel tank in the field of winery, brewery, juice, dairy, biochemical and pharmacy, edible oil, etc.

With 45 years of history Prettech already has 4000 employee, including engineer, office staff, salesman and workers, annual turnover comes up to US$ 20 million, it is the leader of innovation design and manufacturer of Stainless Steel Tanks in China.

Professional design, reasonable prices, fast delivery and rich export experiences make our stainless steel equipment are sold to over 30 countries in the world, the fast & high efficient after-sale services and neverpromised quality make us to keep long-time business relationship with our clients.

Wine Making Equipment

- Wine Fermentation Tank

- Wine Vinificator

- Wine Fermenter

- Red Wine Fermentation Tank

- White Wine Fermentation Tank

- Cone Shaped Fermentation Tank

- Open Top Tank

- Removable Top Fermentation Tank

- Portable Fermentation Tank

- Horizontal Rotary Fermentation Tank

- Automatic Discharge Wine Tank

- Pump-over Wine Fermentation Tank

- Tapered Wine Fermentation Tank

- Punchable Fermentation Tank

- Convertible Fermentation Tank

- Fork Channel Support Fermenter

Wine Storage Tank

- Closed Top Wine Tank

- Wine Holding Tank

- Closed Top Wine Storage Tank

- Bulk Wine Storage Tank

- Portable Storage Tank

- Classic Wine Storage Tank

- Large Wine Storage Tank

- Fork Pocket Storage Tank

Variable Capacity Tank

- Floating Lid Tank

- Variable Capacity Fermentation Tank

- Floating Top Fermentation Tank

Insulated Tank

- Cold Stabilisation Tank

- Energy Efficient Tank

Sparkling Wine Storage Tank

75 Gallon Wine Barrel (about 284 L)

Beer Brewing Equipment

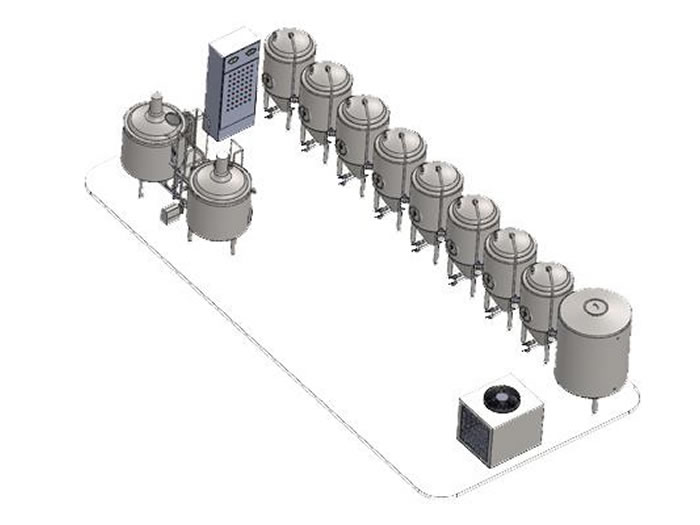

Micro Craft Brewery

Micro Breweries

Brewhouse

- Mash Tun

- Lauter Tun

- Wort Kettle

- Whirlpool tank

Brewhouse System

2 vessel brewhouse

3 vessel brewhouse

4 vessel brewhouse

Beer Tanks - Brewery Tank

Beer Fermentation Tank

- Bear FV

- Unitank

- Uni-fermenter

- Double Wall Fermenter

Bright Beer Tank

- Bear BBT

- Brite Tank

- Beer Bright Tank

- Cider Brite Tank

- Double Wall Bright Tank

- Stainless Steel

Hot Cold Water Tank

Conical Jacketed Tank

Single Wall Beer Tank

- Hot Cold Liquor Tank

- HLT CLT

Support Equipment

cellar package

Turn-key Brewing System

Microbrewery Equipment

Microbrewery System

- Nano System

- Craft Beer System

- Home-made System

- Pilot System

Food Beverage Industry Equipment

Mixing Tank

- Dairy Mixing Tank

- Juice Mixing Tank

- Food Mixing Tank

Storage Tank

- Edible Oil Storage Tank

- Vinegar Storage Tank

Jacket Kettle

Biochemical Pharmacy Equipment

Fermentation Tank

Crystallizing Tank

- Crystallizer

Bioreactor Tank

Tank Farm

- Spirit Tank Farm

- Wine Tank Farm

- Platform Laddle

- Pipes Valves

Even if you do not find the product you are looking for in the list Vine Blossom with its partners will work actively to find out a solution.

Pump-over Fermentation Tank

Pump-over fermentation tank is primarily intended for maceration of grape pomace, but it also can be used as a classic wine storage tank.

Features:

- The circulation pipe and spray ball enable the must be pumped over the cap, which helps the maceration.

- Slope bottom provides an easy discharge of liquid.

- The large rectangular manhole makes the emptying and cleaning of the tank inside easy and simple.

- Cooling jacket is for controlling the fermentation temperature perfectly.

- Maximize color extraction without compromising efficiency.

- High volume pump-over systems for faster cap wetting

Configurations

Cylindrical shell, Conical top, Slope Bottom, 4 legs with adjustable feet, Top round manhole, Side rectangular manhole, Dimple cooling jacket, Glycol water inlet/outlet, Pump-over system, Filtering grid, Drain outlet, Thermometer, Breathing valve, Sampling valve, Level gauge, CIP system, Butterfly valve&tri-clamps, Lifting lugs.

Variable Capacity Wine Fermentation Tank

This type of tank is suitable for processing smaller quantity of wine. The floating lid enables to remove the air in any level of the liquid in the tank.

Features:

- The tank is equipped with a manual windlass for an easy lifting and sinking of the lid.

- Reinforced upper rim gives the tank strength and stability and prevents any deformations of the shell.

- Slope bottom provides an easy discharge of liquid.

- The large rectangular manhole makes the emptying and cleaning of tank interior easy and simply.

Configurations:

Cylindrical shell, Floating lid, Lifting arm & windlass, Air pump with pressure gauge, Breathing valve, Slope bottom (conical bottom optional), Supporting legs (adjustable feet optional), Side rectangular manhole, Dimple cooling jacket (cooling coil), Inlet/outlet, Drain outlet, Thermometer, Sampling valve

Brewhouse

Brewhouse have all the components which are necessary to brew beer, from malt mill, Mash tun/Lauter tun, Kettle/Whirlpool tank, heat exchanger, pumps, working table to pipelines. Vessel height& diameter depends on the ceiling height and brewer s habits and brewing capacity, beer types.

According to brewing capacity, micro brew house have mainly 3 types of combo depending on vessel numbers:

- 2-Vessel Brewhouse

Mash/Lauter Tun/ + Brew Kettle/Whirlpool

Mash/ Brew Kettle/Whirlpool+ Lauter Tun - 3-Vessel Brewhouse

Mash/Lauter Tun + Brew Kettle + Whirlpool

Mash Tun+ Lauter Tun + Brew Kettle/Whirlpool - 4-Vessel Brewhouse

Mash Tun + Lauter Tun + Brew Kettle + Whirlpool

Heating method for brewhouse can be direct fire, steam/gas or electricity, it makes different design and specifications of vessels, e.g. fire box would be adopted when the vessel is heated by direct fire.

According to client s budget and requirements, the brewhouse system can be controlled by manual, automatic or half-automatic.

We d like to custom and produce brewhouse for different clients coming from restaurant, brewpub or microbreweries, if needed we can also help to install and commission the system.

Are you going to consult customized brewhouse system information with a reliable Brewhouse manufacturers and suppliers? Prettech Machinery is always at your service.

Craft beer system

Configuration

- 2 vessel: Mash tun(M.T.)/Lauter tun(L.T.)+Kettle/Whirlpool(WHP)

- 3 vessel: Mash tun(M.T.)+Lauter tun (L.T.)+Kettle/Whirlpool(WHP)

- 4 vessel: Mash tun(M.T.)+Lauter tun (L.T.)+Kettle+Whirlpool(WHP)

- Hot Liquor Tank (HLT)

- Plate heat exchanger,

- 1 wort pump, for bigger brewhouse 1 additional HLT pump is necessary

Controlling panel

- Integrated processing piping with valves&tri clamps for wort and hot liquor, CIP water.

- Platform with wort-checking table and stairway.

- PRT microbrewery system features

- Cost effective,

- Easy to operate,

- Save energy consumption.

We design, fabricate and install the brewhouse with 2-vessel,3 vessel,4 vessel and combi system based on various production output for small and medium brewpub, restaurant, and microbrewery, capacity range from 1BBL to 50BBL(1 BBL=117 L). Heating way can be electric, direct fire and steam, based on local energy price and brewhouse capacity. All of the stainless steel gears are sanitary and TIG welded, easy to clean and convenient to operate, the heating exchanging designing help to improve energy utilization.

Contact us for more information

We have the right solution for you